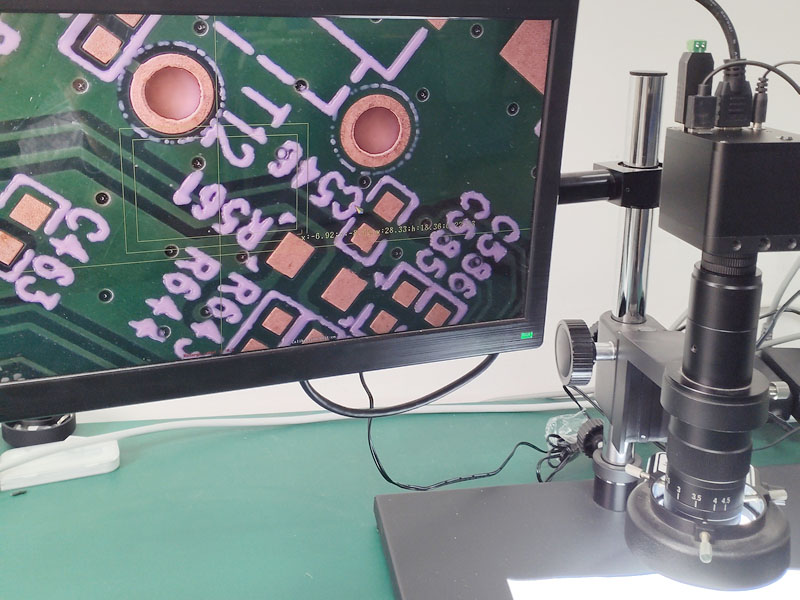

From Standalone Imaging to Intelligent Ecosystem: How Our Custom RS485 Interface Bridges Microscopy with Automated Systems

Introduction: The Power of Integration

In today’s demanding scientific and industrial environments, isolated instruments create bottlenecks. The true breakthrough comes from integration. That’s why we’ve engineered a groundbreaking customization: an RS485 microscope camera integration solution that transforms standalone imaging into a networked, intelligent component of your automated workflow.

Why RS485 Protocol is Ideal for Microscope Camera Integration

RS485 microscope camera integration is not just an add-on; it’s a strategic upgrade. The RS485 standard enables:

- Robust long-distance communication, perfect for large facilities.

- Multi-device networks, allowing one camera or many to work in unison with other equipment.

- Superior noise immunity for reliable operation in electrically noisy industrial settings.

- True bi-directional data exchange, making the camera an active, communicative node in your system.

This level of microscope camera integration moves you beyond simple image capture into the realm of process control and data intelligence.

Core Advantages of Our RS485 Microscope Camera Integration

- Seamless System Integration

Achieve direct with Laboratory Information Management Systems (LIMS), PLCs, or automated stages. Our camera communicates natively, eliminating the need for adapters and simplifying your setup. - Unified Centralized Control

This integration allows you to command and configure multiple imaging stations from a single dashboard. Perfect for quality control lines or core facilities managing high throughput. - Industrial Reliability for Demanding Environments

Where USB fails, our RS485-integrated microscope camera thrives. Its robustness ensures consistent performance in manufacturing plants, remote monitoring stations, and other challenging locations. - Enhanced Data Traceability & Workflow Automation

Automatically embed critical metadata (like timestamp, calibration, and sample ID) directly into image files upon capture. This integration is key for compliance and automating documentation workflows.

Transforming Industries with RS485 Integration

- Automated Quality Control: Implement a closed-loop RS485 microscope camera integration where inspection systems direct the camera to specific defects, capturing and analyzing images in real-time.

- Smart Laboratory Networks: Facilitate multi-user microscope camera integration in shared labs. The camera automatically adjusts settings based on user-specific protocols pulled from a central database.

- Remote & Hazardous Area Monitoring: Reliable long-distance RS485 integration enables experts to control microscopy and receive data from anywhere safely.

- Pharmaceutical & Compliance Labs: Maintain impeccable audit trails through automated, data-rich image acquisition powered by deep system integration.

Engineering Your Custom Solution

Our RS485 microscope camera integration is built into our proven hardware platform. You retain all premium imaging features—high resolution, precise measurements, time-lapse—while gaining industrial-grade connectivity.

Technical Specifications of the Integrated System:

- Protocol: RS485 (EIA-485), enabling seamless microscope camera integration.

- Compatibility: Modbus RTU standard for easy integration.

- Network: Supports daisy-chaining for multi-camera integration.

- Performance: Maintains full imaging specs alongside robust communication.

The era of isolated microscope stations is ending. With intelligent RS485 integration, laboratories and factories can achieve unprecedented levels of automation, traceability, and efficiency. This customization exemplifies our commitment to solving real-world integration challenges – not just selling cameras, but delivering complete imaging solutions.